PICK UP

Aiming for the world with traditionally crafted pot stills.

The only whisky distillery in Hokuriku.

<Part 1>

#Pick up

稲垣貴彦さん from「三郎丸蒸留所」

writer:Ryoko Kuraishi

Mr Inagaki (right), the fifth generation of the Saburomaru Distillery, and Shohei Oigo, the 15th generation of the Laiko Manufacturing Company.

Toyama Prefecture, surrounded by the Tateyama mountain range with its 3000 m high peaks of the Northern Alps and Toyama Bay, is known as a treasure trove of great water, and sake brewing has been active in the area since ancient times.

One such sake brewery is Wakatsuru Sake Brewery, founded in 1862.

Since 1952, the brewery has adopted a two-fold approach: brewing sake in winter and distilling whisky in summer, using Toyama Prefecture's famous water as the brewing water.

At Saburomaru Distillery, which boasts a tradition of being the only distillery in Japan to make whisky for more than half a century, newly appointed blender Takahiko Inagaki is currently pushing ahead with a major renewal.

First, he set up a crowdfunding campaign in 2016 to raise funds to overhaul the aging building and production facilities.

It also updated its own mash tun, which was converted from a rice soaking tank, for the first time in half a century, and installed the latest model from Miyake Seisakusho.

Prototype machines in stainless steel, pure copper and copper-tin (douzin) alloys.

The world's first pot still made from cast iron (imo)!

The pot still was the highlight.

The world's first cast pot still was developed.

At the time, we only had one 30-year-old distillation unit.We had to do the first distillation and redistillation with it, which was very inefficient.

All the other equipment was also old, so it inevitably tasted like 'old local whisky'.

We have been making whisky with a focus on heavy peated whisky since 1952, but we are losing the essential peaty flavour.

So we decided to renew our facilities, including our pot stills."

When we contacted overseas pot still manufacturers such as Forsyth, we were told that it would take two or three years to deliver the product.

In Japan, it was also taking time due to the construction of a series of distilleries.

If it took three years to introduce pot stills, we would never be able to start making real whisky.

That is when Mr Inagaki turned to the traditional craft of Takaoka copperware, also from Toyama Prefecture.

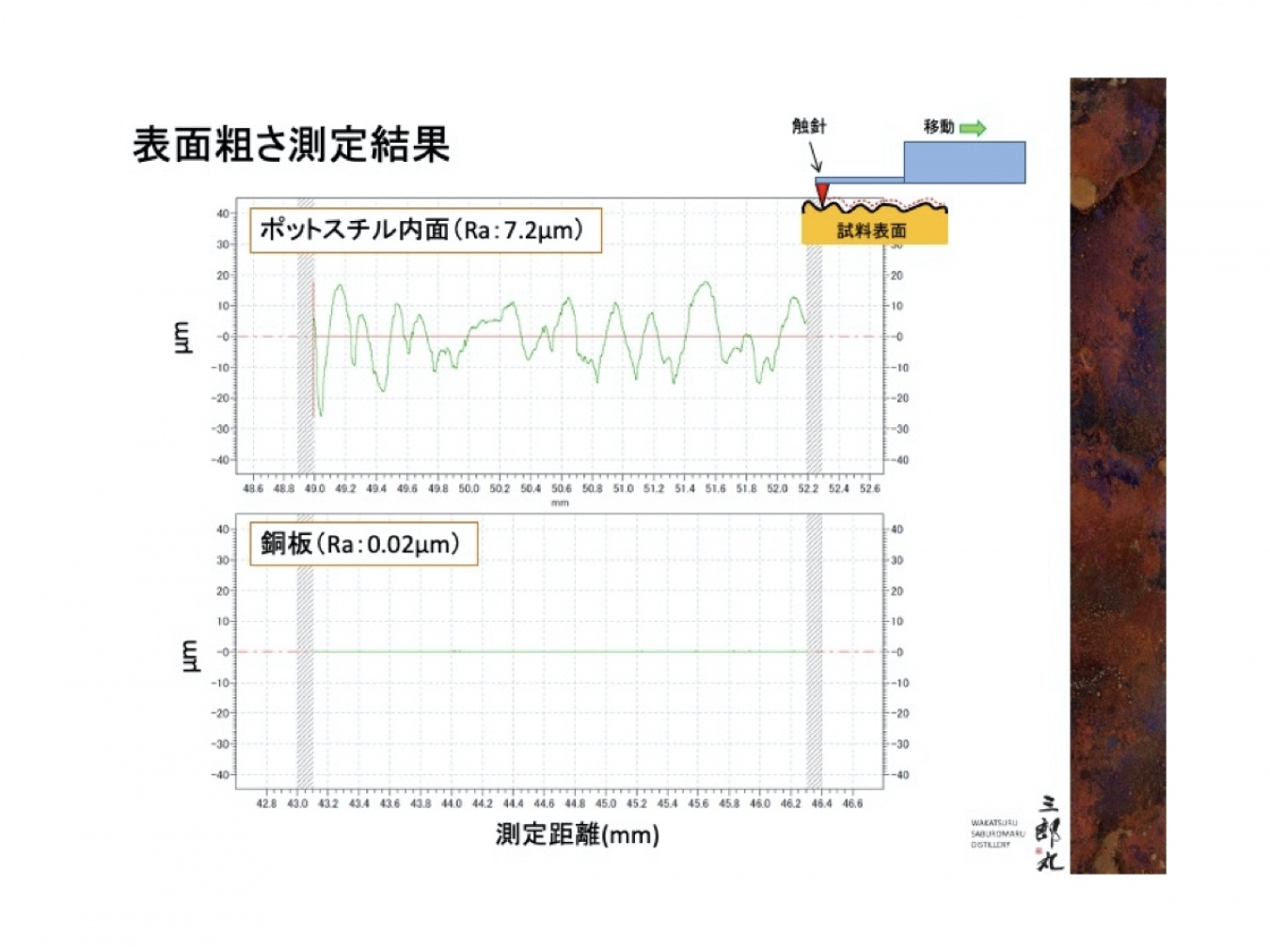

Measurements of the smoothness of the internal surfaces of conventional pot stills and 'ZEMON'.The conventional type with tapped copper plates is smooth, while the 'ZEMON' has fine irregularities.

Takaoka City is a major production centre, responsible for 90% of Japan's copperware production.

The history of Takaoka copperware dates back 400 years to the time of Kaga feudal lord Maeda Toshinaga.

Initially, the company produced daily necessities such as pots, hoes and agricultural tools, but from the mid-Edo period onwards, it began to deal in bronze castings.

In the casting process, a mould-maker first makes the original mould, replaces it with a sand mould, and then pours liquid bronze into the mould.

The mould is removed, polished, coloured and finished.

The division of labour in these processes has enabled Takaoka to take their specialist skills to the extreme.

Takaoka copperware boasts some of the best casting technology for everything from detailed work such as bronze statues to oversized bells such as Buddhist bells.

We thought that if we could make oversized Buddhist bells (3m in diameter and 5m high), we could also cast pot stills.

Mr Inagaki went to Laoko Seisakusho, which is known for its production of Buddhist bells.

First of all, we decided to compare and verify conventional pot stills, i.e. those made of sheet metal, which are welded by beating copper, and those made by casting.

First of all, when it comes to the production of pot stills, casting is much quicker than sheet metal, which is beaten and shaped, and as long as you have a mould, you can increase production.

In terms of function, casting has thicker walls and can withstand the wear and tear on the copper that occurs during the distillation process.

Besides, sheet metal pot stills are made of pure copper, whereas cast pot stills are an alloy of copper and tin.

We wanted to know how this tin would work."

It is made from a special alloy from which lead has been extracted.Because of this, Lao Zi says he had to redo the process two or three times due to problems with the 'hot water circulation', which involves pouring the molten alloy into the mould.

Copper-tin alloy, which was more suitable for whisky making than pure copper!

In response to Mr Inagaki's request, Shohei Oigo, the 15th generation of Oigo Manufacturing, produced a prototype with a capacity of 2 l in a copper-tin alloy.A comparison study was conducted with three patterns of the same size: pure copper, copper-tin alloy (=... castings) and stainless steel.

'We asked the Liquor Research Institute to appraise the components of the spirits distilled in the prototype still.

It was expected that the stainless steel still produced a sulphur smell (sulphurry), but to our surprise, the results showed that the copper-tin alloy casting was equally or more effective than the conventional pure copper one.

So we officially started the development of the actual machine."

Meanwhile, how did Oigo Seisakusho feel about the development of the cast pot still?

Let's ask Shohei Laiko, who was in charge of development, how he felt about the development of the cast pot still.

'From the drawings and photos, I thought it would be easy to make.

The shape is similar to a Buddhist bell, and we also produce much larger bells than this one.

In addition, Mr Inagaki says, 'I want it to last longer than before, so I want it to have thicker walls.

It's difficult to make them thin in casting.

That's why we felt that this was a field in which we were rather good at.

However, this was the first time they had seen or heard of pot stills.

In the actual production of the stills, they faced a number of challenges.

Moonglow is the best blended whisky, using the original spirit from the Saburomaru distillery, the 'Jennenmei' of blended whiskies.'Saburomaru 1960', as the name suggests, is a whisky distilled in 1960 and bottled in 2015.'It was distilled by my great-grandfather.We used a hand-wiped glass bottle made in the prefecture to convey the spirit of Toyama's craftsmanship, and as it is 55 years old, we put it on the market for 550,000 yen, but it sold out immediately".Even today, half shots can be tasted for 9,000 yen at the 20,000-yen brewery in the distillery.

For example, the alloy used in ordinary castings contains 3-5% lead, but lead is toxic, so an alloy without lead must be used.

'When lead is added, the hot water runs more smoothly and it is easier to process, but unlike the Brahma bell, it is used for food, so the lead must be removed.

At the request of Mr Inagaki, who wanted to produce a world-class whisky, we decided to meet the strictest European standards (ROHS2 directive).

We decided to have an alloy with a lead content of less than 0.05% specially made by a manufacturer in Takaoka.

Also, as our company mainly produces Buddhist bells, craftsmen tend to carefully craft the outside.

But what is important in a pot still is the inside rather than the outside.We also needed to raise awareness of this."

The world's first cast iron pot still, the result of a trial and error process, was named ZEMON after Jiemon Oigo, the trade name of the Oigo Manufacturing Company.The still was named "ZEMON" after Jiemon Oiko, the trade name of the Laiko Manufacturing Company.

This turned out better than expected.

In the second part, we ask Mr Inagaki about the world-class standard of whisky making he aims to achieve with ZEMON.

Continued in Part 2.

SHOP INFORMATION

|

|

|---|---|

| 三郎丸蒸留所 | |

|

富山県砺波市三郎丸208 TEL:0763-37-8159 URL:http://www.wakatsuru.co.jp/saburomaru/ |

- DRINK PLANET >

- PICK UP >

- Aiming for the world with traditionally crafted pot stills.

The only whisky distillery in Hokuriku.

<Part 1>

![[Drink Planet] Cocktail portal site for bartenders](/img/common/logo.png)

![[Drink Planet] Cocktail portal site for bartenders](/img/common/logo-l.png)