PICK UP

The hottest tool in the bar industry is here!

A closer look at the tabletop decompression distiller from Uzuma Heavy Industries.

- Part I

#Pick up

安永昌平/Yasunaga Shohei from「Uzuma Heavy Industries」

writer:Ryoko Kuraishi

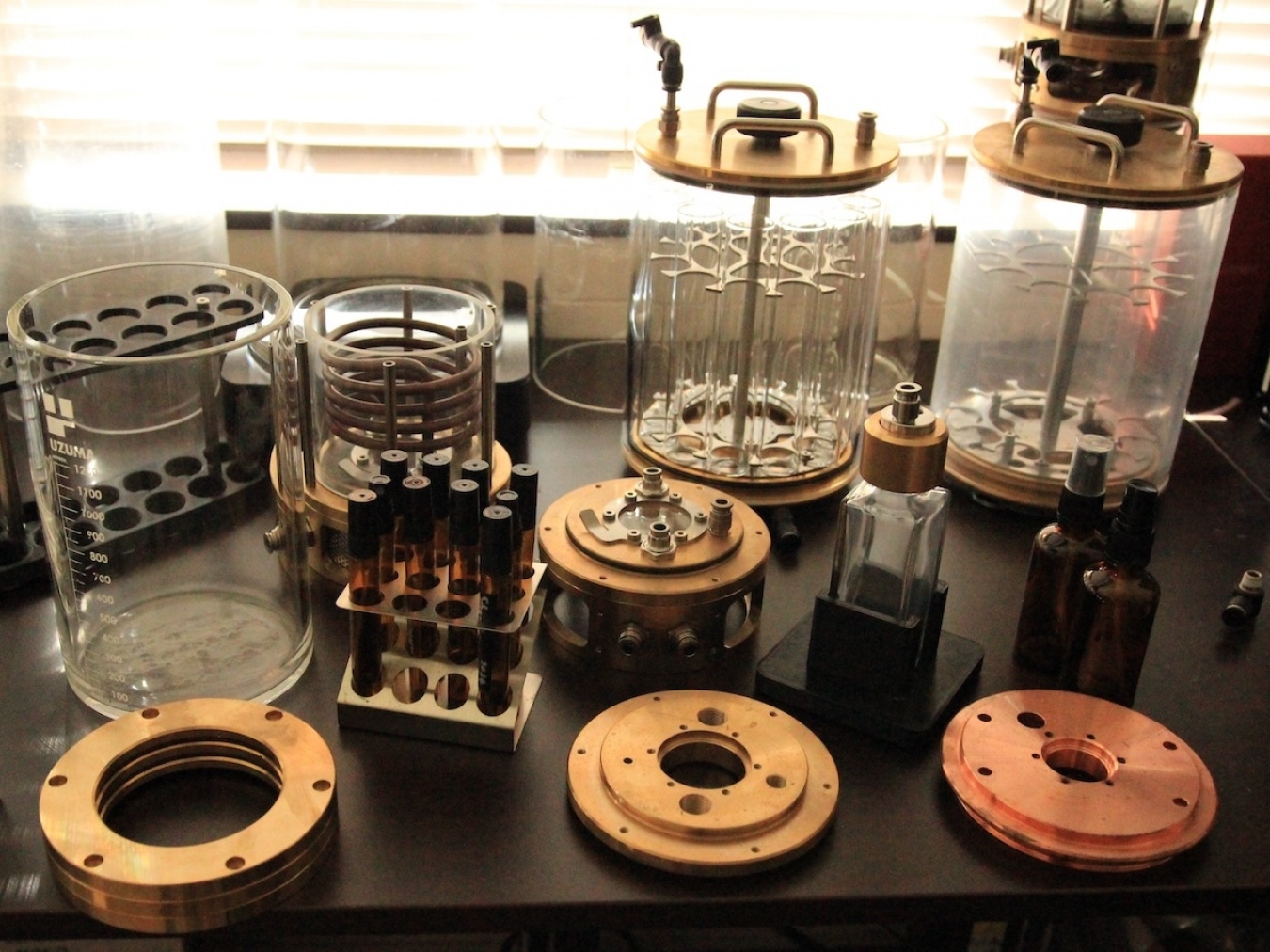

This is the tabletop decompression distillation unit developed by Uzuma Heavy Industries.It is connected to a vacuum pump and a distillate collection bottle to perform decompression distillation.The boiler capacity is 1.8 liters, and a maximum of 900 ml of vacuum distillate can be distilled at one time.The cost is less than 1/4 of a set of rotary evaporators.There’s an option to select a configuration suitable for international use. For pricing, please contact Uzuma Heavy Industries.

Since its general release in the spring of 2024, Uzuma Heavy Industries' "tabletop reduced-pressure distiller" has been enthusiastically received by some bars.

The compact design of this machine is eye-catching, and it makes it possible to distill small batches easily, conveniently, and safely on the bar counter under reduced pressure (i.e., without adding heat, which would damage the aromatic components of the ingredients).

Since the machine uses reduced pressure, the temperature is only 40 degrees Celsius at most, and the aromatic components can be extracted while maintaining the freshness of the ingredients.

Middle cut can also be performed during decompression.The syrup can also be boiled at low temperatures (decompression and concentration).

It can also be boiled at low temperatures (decompression and concentration), so you can make syrup, aromatic distilled water, and compote at the same time.

Vapor infusion is also possible using a basket inside the distiller.

In addition, it has visuals that will win the hearts of gadget geeks.

Mr. Yasunaga is an active engineer currently leading Uzuma Heavy Industries.

Reduced-pressure distillation equipment specialized for the functions required for bars.

Uzuma Heavy Industries is a machine manufacturer by Shohei Yasunaga, a mechanical engineer.

In addition to custom-made machine design, the company develops original tools for bars.

Mr. Yasunaga graduated from the mechanical engineering department in the Faculty of Engineering.

After graduating from graduate school, he worked for a major heavy industrial manufacturer.After working in the design department, he is currently engaged in research and development of new products at a manufacturer of machinery for the chemical and food industries.

He has been making fluid machinery (machinery related to liquids such as air and water) throughout his junior high school, high school, university, and working life.

I built the first prototype in the "cell-like" bachelor dormitory of a major manufacturer, making full use of glass bottles available at home improvement stores and a 3D printer.

He continued to make aromatic distilled water by running a decompression distiller in the bathroom at night.

Left: The large opening allows materials to be fed directly into the machine. Right: Vapor infusion is possible by attaching a basket.

"Although reduced-pressure autodistillation has already become the standard in overseas bars, we felt that the rotary evaporators used in many bars were over-specified.

To begin with, rotary evaporators are experimental equipment designed for special processing, such as that required in chemistry laboratories, so their structures are complicated and difficult to handle.

The machines are also large, expensive in both body and running cost, and the operating noise of the pump is also a concern.

On the other hand, what is required in a bar is to extract the aroma of the botanicals and put it into the drink.

I thought that a compact size reduced-pressure distiller with a simpler design than a rotary evaporator could be used by anyone and would be in demand in bars.

Just as the prototype was being completed, I happened to stop by a bar I found on my trip to Onomichi.When the prototype was finished, he stopped by Soko, a bar he happened to find on his trip to Onomichi.

The owner and I hit it off at the bar, which serves unique cocktails made with herbs, fruits, and medicinal herbs.

When I told him about my own distillation equipment, he said, "I'd love to have one made," and the order was quickly placed.

Here is the first prototype built in the bachelor dormitory. Full of DIY feel!

A few weeks later, on the way to Onomichi to deliver to "Soko," I stopped by Kyushu, where my parents live, and visited bars in Hakata.

When he showed them the distillation equipment he was planning to deliver, several bars in Hakata immediately ordered it.From there, it spread by word of mouth to bars in Hakata.

With this distiller that can be operated on the bar counter, reduced-pressure distillation could become a new standard in bars.With this in mind, we developed a second version of the distiller that was designed to be "displayed on the bar counter.

The second version was updated to be sleeker and more visually exciting, and the specifications were changed to be compatible with IH stove tops.

Since then, we've been asked to hold seminars, and now bars all over the country are installing them.

Rotary Fraction Collector" under development (tentative price ¥250,000).How to use it will be described in the second part!

As the number of stores using the system increased, Mr. Yasunaga received a variety of feedback.All of them are very professional and convincing.

We have been expecting to use vacuum distillation to make aromatic distilled water for fruits and herbs in bars and vacuum distillation to make syrups for colas and tonics, but recently we have been receiving a variety of applications outside of bars as well," said Mr. Kikuchi.

A Japanese confectioner in Kyoto uses decompression distillation to make syrup and aromatic distilled water from gardenias, which lose their aroma in atmospheric distillation, to make Japanese sweets with the delicate aroma of flowers.Miyagi pastry chefs use this decompression distiller to boil off wine and champagne, leaving the delicate aroma intact and making it non-alcoholic, and then use it to create new confections.

It can also be used in place of the gastro vac (decompression cooker) that is familiar in the gastronomy scene, and some cooks use it to concentrate soup stocks and sauces.

In the second part, we will visit the "Cocktail Stand FUREK," which has been using this distillation unit since the spring.In the second part, we visit Cocktail Stand FUREK, which has been using this distiller since spring!We ask Mr. Ryuichi Saito about its usability.

Continued in Part 2.

SHOP INFORMATION

|

|

|---|---|

| Uzuma Heavy Industries 巴波重工 |

|

|

非公開 TEL:非公開 URL:https://www.uzmlab.com/home |

- Drink Planet >

- PICK UP >

- The hottest tool in the bar industry is here!

A closer look at the tabletop decompression distiller from Uzuma Heavy Industries.

- Part I

![[Drink Planet] Cocktail portal site for bartenders](/img/common/logo.png)

![[Drink Planet] Cocktail portal site for bartenders](/img/common/logo-l.png)