PICK UP

Sustainability from a bar perspective

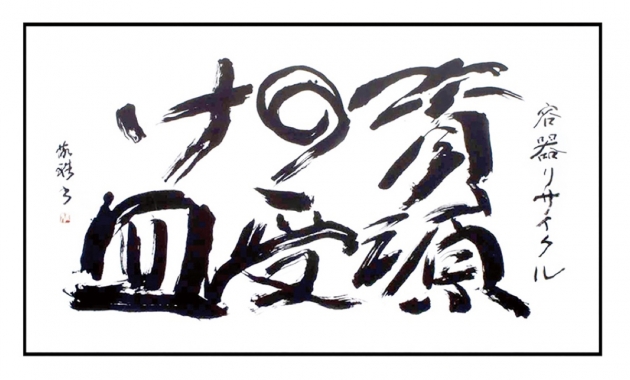

Reusing bottles for a recycling-oriented society!

- Part 1 -

#Pick up

戸部昇/Tobe Noboru from「トベ商事」

writer:Ryoko Kuraishi

A new bottle washing plant was built in Iriya, Adachi-ku, Tokyo in 2021. This large bottle washing machine can wash 25,000 to 30,000 bottles per day.

Looking back at the history of glass bottle reuse in Japan.

Bottles were first distributed in Japan around the middle of the Meiji period (1868-1912).

Tobe Shoji, based in Tokyo, started the bottle recycling business in those early days. The company was founded in 1893!

I am the fourth generation, but the first generation originally ran a rice cracker shop.

One day, I was told by a retired sake brewer, who was a fellow fisherman, that in the West, sake is sold in glass bottles. In the future, we will shift from tokkuri to bottles in Japan as well," and that is when he turned his attention to bottles.

At the time, demand for bottles was growing as domestic beer sales began," said Noboru Tobe, fourth-generation representative director of Tobe Shoji.

At the time, there were resource collectors who pulled big wagons to collect scrap metal, and as he bought bottles from them, he began to hold a large stock of bottles. When they sold these bottles in bulk to liquor wholesalers, they made a much larger profit than they had imagined.

That's when he switched his main business to bottles.

We have been collecting used bottles and putting them back on the market since the days when recycling was not even a word.

Bottles after pre-washing. The label on the side of the bottle remains intact at this stage. Scraps of paper labels removed during the high-temperature main washing stage are recycled back into pulp through an initiative with Oji Paper. However, if plastic labels are mixed in, they cannot be recycled. So, please remove the plastic labels from the bottles when you put them out for collection!

Later, during the second generation, the company began producing Japan's first sparkling wine at the nearby Ministry of Finance's Brewing Experiment Station in Kita-ku.

An official of the Liquor Taxation Bureau ordered a whopping 3,000 bottles.

After World War II, it took a long time for the bottle factories to recover, so there was a high demand for reused bottles until the late 1950s.

It was not until the 1950s that a major change occurred.

A container revolution took place: beer went from bottles to cans, milk went from paper cartons, and soy sauce went from plastic bottles.

Based on social trends, Tobe Shoji decided that the use of disposable containers would increase in the future and turned its attention to recycling in general, including recycling cans and PET bottles as resources.

Nevertheless, Tobe Shoji still maintains a strong commitment to the reuse of bottles and continues its bottle washing business.

Bottles that have been washed twice at high temperature. The label has been removed cleanly. The inspector visually checks the mouth and body of the bottle to see if there is any residue left after washing or rinsing. After this, the bottles are inspected by a high-resolution digital camera.

This is because glass bottles, which can be cleaned and reused to reduce environmental impact, are very suitable for reuse in terms of bottle washing process.

We believe that in the future, when considering the effective use of resources, it is necessary to have the mindset that containers are not for consumption, but for use.

Therefore, we came up with the idea of collaborating with other bottle traders (businesses that specialize in collecting, cleaning, and reselling bottles) in an attempt to encourage reuse."

One of these measures is an initiative with the Co-op.

The key to bottle reuse is the efficient collection of used bottles, and in this regard, the Co-op has a delivery system in place that makes it easy to engage in reuse.

Currently, we clean and reuse about 5.5 million bottles collected by the Co-op each year. It is difficult to collect bottles nationwide, but we have found that it is possible to encourage reuse by working with businesses that have collection systems within a certain region.

Bottles that have passed the high-resolution digital camera inspection are boxed after a final visual check and are ready for shipment. The bottles are then sent to the bottling plants of liquor and food manufacturers.

A typical reuse flow for returnable bottles looks like this.

Products are shipped from bottling plants of liquor and food manufacturers to distributors and retailers.

↓

The product is sent to consumers.

↓

Consumers dispose of used bottles at retailers or for resource collection by the government.

↓

Bottle traders collect used bottles from retailers or government agencies. Bottle trader collects used bottles from retailers or government agencies and transfers them to a bottle washing factory.

↓

Washed bottles are sent to bottling plants of liquor and food product manufacturers. Bottles that cannot be reused are sent to a cullet factory, where they become cullet (glass waste) and are recycled by the bottle manufacturer as raw materials for new bottles.

This process is made possible through the cooperation of distributors, brewers, bottle merchants, bottle washers, and container rental companies.

The main bottles reused at this factory. In addition to hot bottles, various 720ml bottles, and 1 square bottle, the factory cleans bottles for seasonings, jams, and other products.

The state of reuse in the age of the SDGs.

Next, let's take a look at glass bottle reuse in the alcoholic beverage industry.

Tobe Shoji currently washes 300 to 720 ml sake bottles, mainly for sake and shochu manufacturers.

In the restaurant industry, Tobe Shoji has been collecting, washing, refilling, distributing, and selling 300ml sake bottles for two types of PB sake sold at Watami stores since 2009.

Although reuse is costly and time-consuming, inquiries about it have increased dramatically since the SDGs began to be mentioned, and the company feels that there is a growing awareness of the need to contribute to society through their products and business.

Tobe Shoji feels a sense of responsibility not to squelch the momentum of reuse, so we think of ways in which we can help businesses realize their aspirations.

In fact, all of the initiatives being implemented at the Co-op and Watami were realized after the voices of a single member or employee were raised.

The perspective of ordinary consumers, who think "what a waste" and "can't we reuse it for something else," is indispensable for reuse.

We must continue to carefully expand this kind of reuse awareness.

The second part of this report introduces a new reuse project initiated by a liquor manufacturer.

In the future, we can effectively reuse alcoholic beverages through further collaboration with manufacturers and liquor retailers," says Tobe, focusing on Wellness Gin's efforts as an example of such collaboration.

To be continued in Part 2.

SHOP INFORMATION

|

|

|---|---|

| トベ商事 | |

|

(本社)東京都北区王子5-10-1 TEL:03-5902-3202 URL:https://www.tobeshoji.co.jp |

- Drink Planet >

- PICK UP >

- Sustainability from a bar perspective Reusing bottles for a recycling-oriented society! - Part 1 -

![[Drink Planet] Cocktail portal site for bartenders](/img/common/logo.png)

![[Drink Planet] Cocktail portal site for bartenders](/img/common/logo-l.png)